Description

Project Components

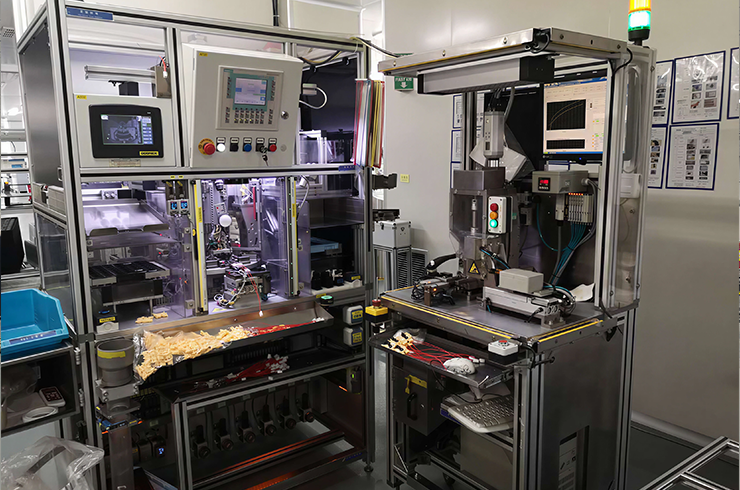

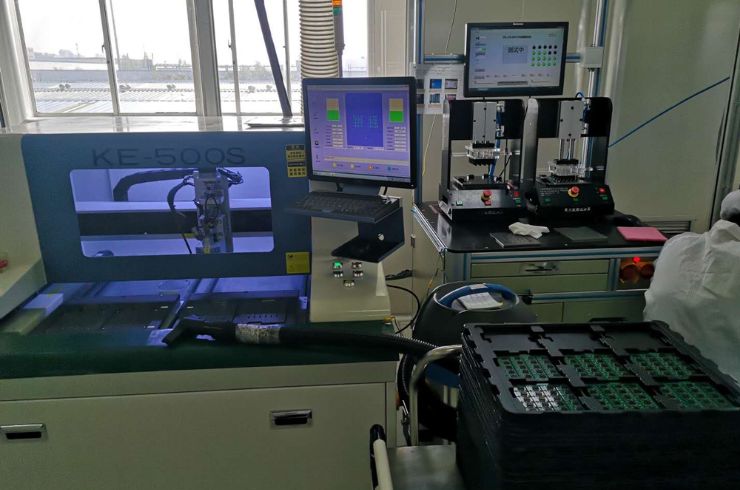

Automated feeding/multi-station pressing; laser welding; high-precision calibration; temperature compensation; EOL testing; unloading.

Advantages

• Precision assembly and laser welding ensure structural integrity.

• Intelligent calibration system enables automatic accuracy compensation.

• Full-condition simulation testing verifies environmental adaptability.

• Modular and flexible design supports rapid switching between multiple product categories.

• Complete recording of test data establishes a digital product archive.