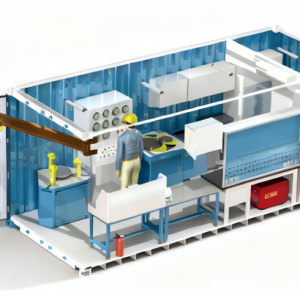

Description

Product Parameters

• Production Cycle Time: 8 seconds/pcs

• Process Capability Index: CPK: >1.67

• First-Pass Yield: ≥99%

• Staff Requirement: 1 (or 2)

Production Line Features

• Employs a Siemens industrial-grade PLC control system, ensuring precise commands and stable, reliable operation.

• Configured with high-precision XY-axis servo motion modules, achieving accurate positioning and smooth, rapid response.

• Equipped with dual safety start-up circuits and high-resolution optical gratings, constructing a comprehensive safety protection system.

• Supports rapid tooling changeover, with changeover time controlled within 20 minutes, improving production flexibility.

• Equipment force control accuracy ≤1%, repeatability accuracy 0.01mm, achieving micro-level process control.