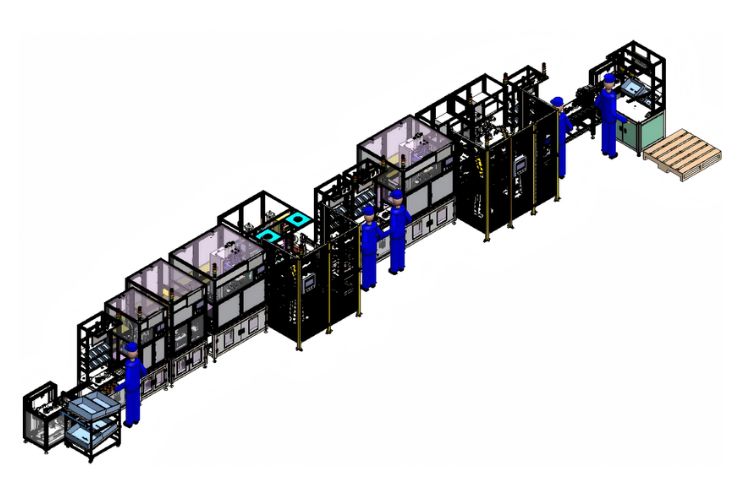

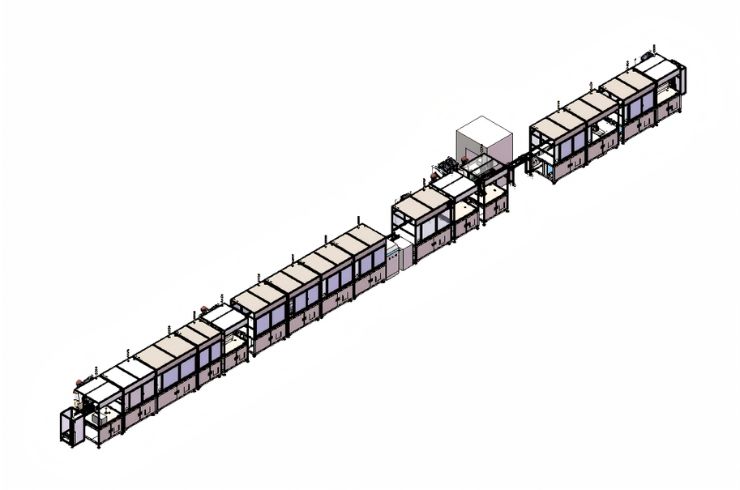

Description

Project Components

• Manual component assembly;

• Thermal matting of PCBA boards;

• Automatic soldering;

• AOI inspection;

• Seal assembly;

• Automatic back cover locking;

• Automatic assembly;

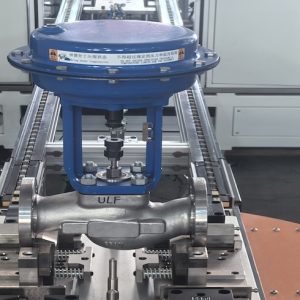

• Air tightness test 1; Material loading; Load performance testing; Manual bushing pressing and mounting bracket installation; Welding;

• Air tightness test 2; Power-on testing; Laser marking; Unloading and packaging.

Advantages

• Utilizes robotic laser welding technology for precise control of welding depth.

• Equipped with a multi-sensor detection system for real-time monitoring of assembly quality.

• Helium leak detection throughout the entire process ensures zero leakage.

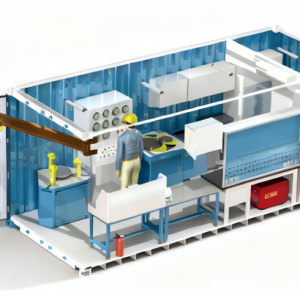

• Modular and flexible design supports rapid switching between multiple models.

• Full lifecycle data traceability establishes a digital quality archive.