Description

Project Components

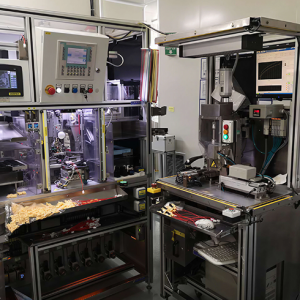

Online marking; heater assembly; airtightness testing; electrical performance testing; heating without electrical performance testing; cooling; automatic leak and resistance testing; material unloading.

Advantages

• Precision press-fitting and laser welding ensure the connection strength and sealing of core components.

• A full-process helium leak detection system achieves zero-defect control of micro-leakage.

• High-precision flow and response testing verifies dynamic adjustment performance.

• Modular flexible unit design supports rapid switching between multiple platform products.

• Key parameters are traceable throughout the process, building a closed-loop quality data system.