Description

Product Parameters

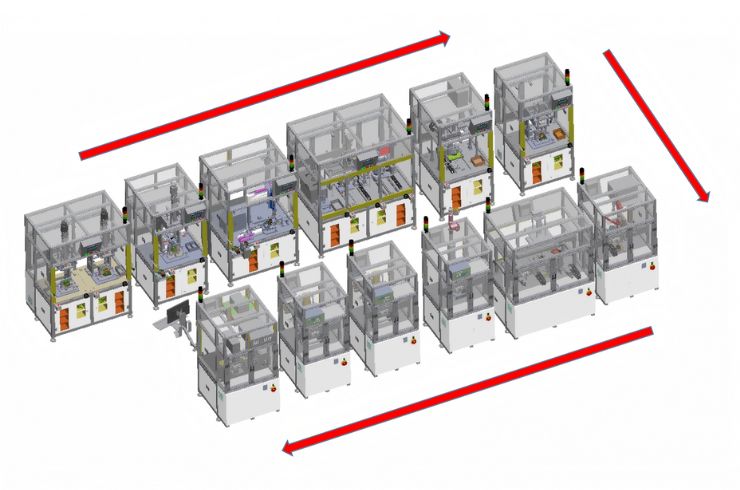

Production cycle time: 60s, Total equipment: 12 units, Number of operators: 9

Project Components

Pressing bushings and pins/Pin and bearing assemblies/Sector gears and laser welding/Magnet installation and hot air riveting/End cap assembly/Motor fixing and testing/Intermediate gear and cover plate assembly/Flow testing/Flow channel airtightness testing/EOL calibration and testing

Advantages

• Precision press-fitting and intelligent tightening ensure critical assembly quality.

• Machine vision-based end-to-end inspection ensures proper component assembly.

• High-precision flow characteristic testing verifies product performance.

• Modular and flexible design supports rapid switching between multiple models.

• Full traceability of production data enables refined quality control.