Description

Product Parameters

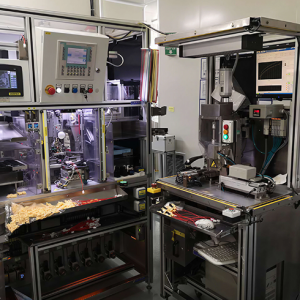

Production cycle time: 25s, Total equipment: 42 units, Number of operators: 14

Project Components

Motor core assembly, precision grouping of moving/stationary discs, modular assembly of components, housing assembly, sealing detection system, electrical system integration, performance testing system, final processing.

Advantages

• Precision press-fit technology ensures high-quality assembly of core components.

• Fully automated helium leak detection ensures zero defects in sealing.

• Comprehensive end-of-life (EOL) testing verifies full performance coverage.

• Modular flexible design supports rapid switching between multiple models.

• Clean environment production meets automotive-grade quality requirements.