Description

Product Parameters

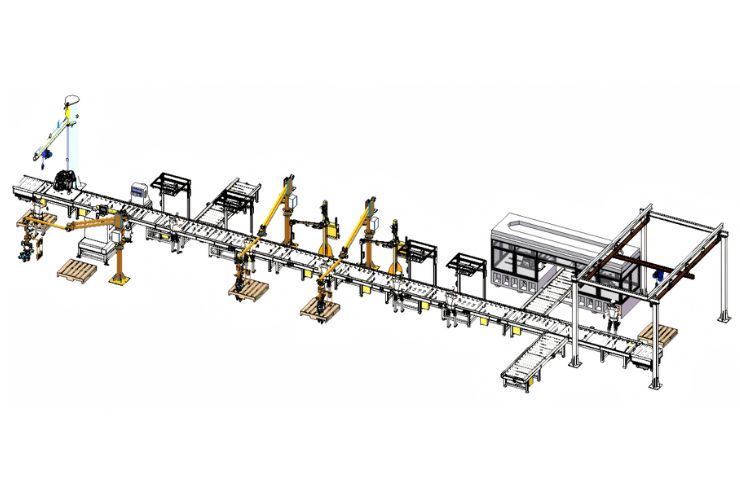

• Production Cycle Time: 500s

• Total Number of Units: 12

• Number of Operators: 8

• Project Components:O-ring assembly, pressing and testing / Reducer assembly / Left and right axle housing assembly / Reducer airtightness testing / Left and right axle housing tightening / Left and right half-shaft assembly / Left and right half-shaft tightening / Wiring harness assembly / EOL (End-of-Life) testing

Production Line Features

• High-precision robotic assembly ensures the quality of core component assembly.

• Full-process automated testing covers critical insulation/EOL (End-of-Life) testing.

• MES (Manufacturing Execution System) provides end-to-end data traceability, establishing a complete quality data chain.

• Modular and flexible design supports rapid changeover across multiple platforms.